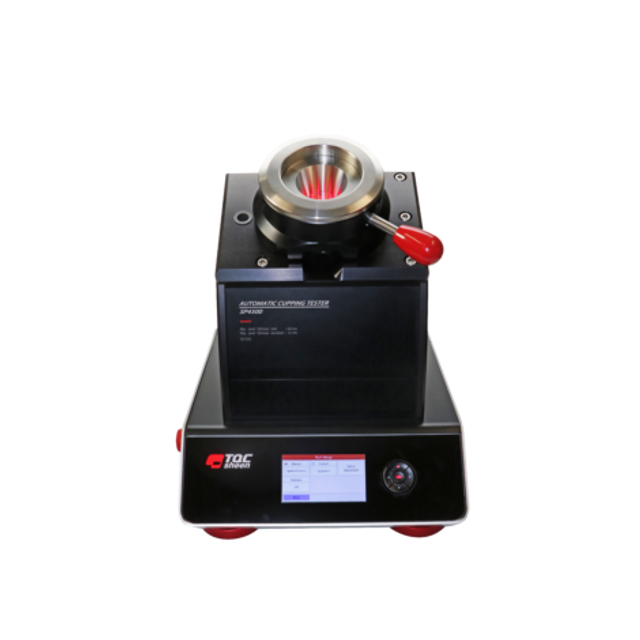

Product Description

TQC Sheen Automatic cupping tester to perform a cupping (Erichsen / Dent) test on coated steel panels to define the resistance of paint, varnish, or related products to cracking and/or detachment from a metal substrate when subjected to gradual deformation by indentation under standard conditions.

The test is either used as a “pass/fail” test by testing to a specified depth or defining the minimum depth at which a coating fails by gradually increasing the indentation.

Constant deformation

The ISO1520 standard requires panels to be slowly deformed at a steady rate between 0,1 mm/s and 0,3 mm/s without interruption. Especially with thicker steel panels hand-operated testers not always allow an uninterrupted deformation. The Automatic cupping tester is driven by a micro-step-controlled electromotor which allows precise and steady deformation with 0,01 mm steps. Uniquely this deformation can be paused/resumed.

Unique Interface

Each Automatic cupping tester is equipped with the Triple I ® Navigation Tool. This Intelligent Illumination Interface guides the operator through the TQC Sheen lab-machines. At each step of the operating menu, the interface detects which buttons are active and indicates these by means of an illuminated red center This results in a very intuitive operating system that is enhanced with information on the machine’s full-color display.

Numerous set-ups

The Automatic cupping tester has numerous set-ups. The custom set-up optionally is password-protected, and after each set number of tests runs statistics are shown. Also, the illumination of the test specimen can be set-up. To guarantee maximum visibility of all types of surfaces including high gloss, matte, or colored samples the TQC Sheen Automatic cupping tester is equipped with a complimentary light system of which the colors can be changed to achieve maximum contrast. The strength of the LEDs is adjustable as is the direction of the light source.

The TQC Sheen Automatic cupping tester has a TQC Sheen-Bus connection (LinQ system not included).

Qualicoat

The cupping test is mandatory in Qualicoat and QIB accredited laboratories.

Standards

DIN-EN 13523-6, EN-ISO 1520, DIN 53156, DIN 53232, BS 3900-E4, NBN T22-104, NFT 30 019. Look up the appropriate standard for the correct execution of the test.

Specifications

Max. sample thickness: : 1,2 mm (steel or aluminum)

Max. sample width : 95 mm

Max sample length : infinite

Punch diameter : 20 mm /hardened steel

Die diameter : 27 mm /hardened steel

Gauge resolution : 0,01 mm

Cupping Range/Stroke : 14 mm

Displacement per revolution : 0.50 mm per handle revolution

Instrument Height : 370 mm (excl lamp/magnifier)

Instrument diameter : 230 mm (excl. lamp holder)

Cylinder Diameter : 236 mm

Base diameter : 300 mm

Total weight : 16 kg.

Materials : Anodized aluminum, Stainless steel, Powdercoated steel, Tungsten Carbide

steel

my account

my account

PRODUCT DATA SHEET

PRODUCT DATA SHEET