3 benefits of great 3D surface profiling

Posted by Tom Swan on Mar 28th 2020

| 3 benefits of great 3D surface profiling | |||

| EXTRACT

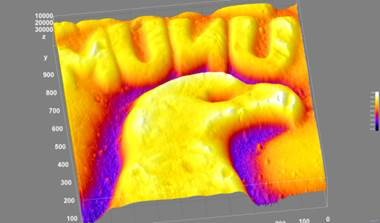

This gauge allows for useful 3-D surface profile readings. ARTICLE CONTENT There are several ways to obtain a surface profile, including Testex Tape, a visual comparator or spring micrometer. If you want the most complete image and reading possible, though, you'll need the latest tools for 3-D rendering. M-Test offers the DeFelsko Positector 6000 RTRP Probe for a complete series of readings, including an accurate surface profile. Surface profile is probably the most critical part of a coating system. It has been proposed for many years that it is not only the height of the profile was important but that the number of peaks per inch or cm is also critical. This is referred to as peak density. The reason peak density has never been specified is the lack of field equipment that could measure it. The standard way to measure peak density in the past was a surf test. This is an instrument with a diamond stylus that is pulled over the surface and counts the peaks and valleys. The limitation is it only measures in a straight line and only for 1 cm distance. It is best used on a flat horizontal surface and is more suited for the lab than the fields.

With the advent of the Positector 6000 3D surface profile probe, peak density can now be easily measured in the field. #1: Get a better bond Once the industry compiles the necessary data, the accuracy of an imaging device could save you more money in the long run if you have a clear understanding of the peak from the beginning. After the surface has been blast-cleaned, you have a clear opportunity to prepare for future coatings if you have a reliable image of the steel to start with. "You have an opportunity to prepare for future coatings if you have a reliable image of the steel." With the abilities of a 3-D imaging tool such as Gwyddion, which is open source software, you can verify that a surface has the profile right depth as well as the proper peak density to maximize the bonding of the coating to the surface. #2:Integration with

other devices It should be noted that due to the file size, the RTRP probe only works with the Advanced body and you can only store one image at a time which must be downloaded before you can take another image. The software of choice, which is free, is Gwyddion #3: Simplification M-Test has a full inventory of the best tools for measuring surface profiling and other coating testing testing: Contact us today orvisit our store to learn more. CATEGORIES In's and Out's of testing tools SOURCE http://www.defelsko.com/technotes/profile/surface-profile-and-adhesion. | |||

|

| IMAGE CAPTION

Get accurate 3D readings from an up-to-date surface profile gauge. | ||

my account

my account  Different types for Surf testers.

Different types for Surf testers.