How much precision and Accuracy do we need?

Posted by Tom Swan on Mar 28th 2020

How much precision and Accuracy do we need?

In the inspection business we should be more concerned with Accuracy than Precision. But how concerned should we be and what is the difference between the two.

Several years ago, Mark Schilling wrote an article about the difference between the two terms. I will cover the difference briefly but for a more comprehensive understanding you can read his article on the DeFelsko website at: https://www.defelsko.com/resources/coating-adhesion-testing-in-accordance-with-astm-d4541-sticky-business.

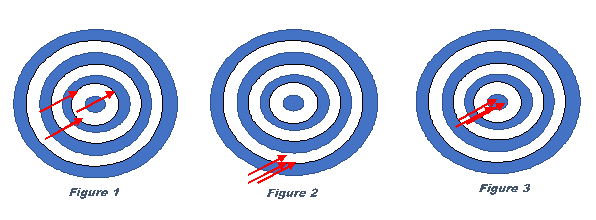

Figure 1 Shows good accuracy with the darts spaced evenly around the bullseye but the precision is bad as they are spaced around they bullseye.

Figure 2 show great precision but poor accuracy. The darts are placed closely together but are not near the bullseye.

Figure 3 shows good Accuracy and god Precision. The darts are spaced accurately inside the bullseye.

When doing coatings inspection, I am sure you have come across situations where the contractor blasted a full area or painted a full area and the readings were all close but were not in range. The contractor had good precision but poor accuracy.

Every year I help Judge the Houston Coating Society Painters Competition. A couple of years ago while measuring Dry Film Thickness on one of the contest panels, after taking all the readings, they were the only team to hit the range of the coating in accordance with the specifications. The problem is while they hit the average, not one of the DFT’s was in range. They had great accuracy but very poor precision.

On a good project, hopefully the readings will all be in the range required by the specifications indicating the contractor had both precision and accuracy.

How Much Accuracy Do You Need

Let’s take a look at some of the tests we run on a typical project.

Temperature – RH – Dew Point

Ambient temperature readings are an important part of any project. Ambient Temperature, Surface Temperature, RH and Dewpoint. When taking readings, we do not only need to account for the accuracy of the instruments but also where and when we take the readings.

Assume we are paint the exterior of a tank. If you are using an electronic meter, slowly walk around the tank taking about 10 to 12 readings. It is more than likely the readings at each location will be different and by them time you get back to the first location, that reading may be different. Then start about 50 feet from the tank and walk towards it. As you get closer to the tank, the readings will probably change. Location is as important as the accuracy of the meter.

The accuracy on ambient temperature on most meters is about 1 to2oF at a given location. Factors such as shade or sun, on top of a ditch or in a ditch, in a tank or outside of a tank can all effect readings. If your meter is off 1 or 2 degrees in one direction and the other meter is off in the opposite direction, you could be looking at 3 to 4 degrees difference between calibrated meters.

Most relative humidity meters are 3% to 5% in accuracy. The above comments apply but this means two meters can be right and read 6% to 10% and both be in spec. While I would not expect that much of a difference, 3% to 5% difference between two meters is within specs between two different meters.

Since Dew Point is calculated from these parameters, you can also get a variation in dewpoints. Which readings are correct? Trends tend to be more important than absolute readings.

Dry Film Thickness

Most type 2 (electronic) DFT gauges have 1% precision. This accuracy is dependent on the meter being properly adjusted. When zeroing your meter, it is important to zero your meter on the surface being tested. If you zero on a flat surface and measure on a blasted profile, you will have 1% precision but may have poor accuracy. Assuming you have a 3 mil surface profile and zero on a flat surface, your accuracy could be off by up to 1 mil or more. This error is called a magnetic base reading and is adjusted out by zeroing on the surface profile.

“Don’t get hung up over precision and ignore accuracy”

I see inspectors get hung up over readings being out by 0.1 mil which is 100,000th of an inch and do not worry about properly zeroing the gauge.

Adhesion

Adhesion testing does serve a useful function in our industry but again suffers from precision and accuracy. If you want a more detailed explanation go the to the Defelsko link at the beginning of the article. If you look at the ASTM table in D4541 it gives you the accuracy of the various types of adhesion testers. This is the error table from D4541 for the different types of adhesion testers.

From Mark Schillings paper:

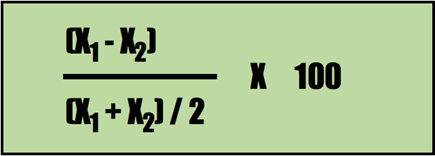

The table shows that depending on instrument type, the acceptable percentage difference between two values may be between about 25% and 58%. That provides a clear indication that the test is quite variable, but an example helps. For a type IV instrument used in the same laboratory, Table 1 of ASTM D4541-02 gives the coefficient of variation as 8.5%, there are 48 degrees of freedom, and the maximum acceptable difference is 29%. The difference in percent relative to two test results is determined by the simple equation below.

Now consider two test values: 2,100 psi and 1,600 psi. Plugging these into the equation gives a result of 27%, which is less than the 29% maximum acceptable difference given in the ASTM table. The stated precision of the test method is so poor that neither of these two values, 2,100 psi or 1,600 psi, can be declared to be the one that is correct. With a very small sampling of only a few measurements, these two values should rightfully be regarded as pretty much the same result. That’s not common sense, but that’s precision for you, or lack thereof.

Many instruments vary in accuracy and precision. The point of this blog is don’t get too hung up on “numbers” without understanding what they really mean. A value can be out of spec but well within the tolerance of the measurement errors. When number are out of spec, be aware of the tolerance of the measuring instruments.

I would like to thank Mark Schilling, who was one of the smartest people I know, for imparting a lot of his knowledge to me. Unfortunately, ha passed away a couple of years ago but left a wealth of information that has contributed a lot tour industry.

KEY WORDS: Accuracy, Precision, Dry Film Thickness, Relative Humidity, Temperature, Dry Film Thickness

my account

my account